Final Project

NMM

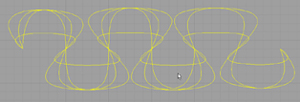

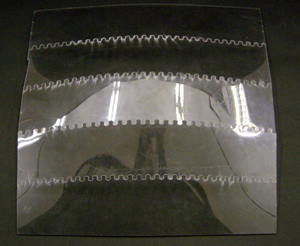

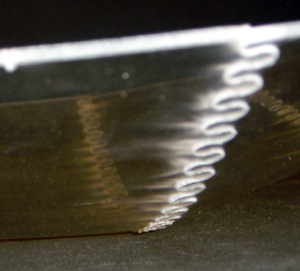

Modeling of a pressure fit puzzle joint in a material to determine the optimum

combination of material thickness, surface friction and joint size and depth.

Potentially differentiating between in plane forces and shear forces.

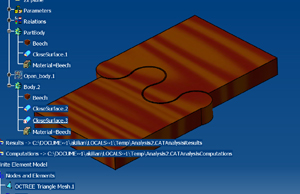

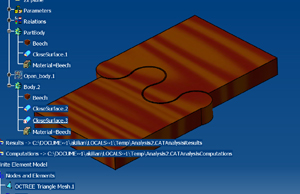

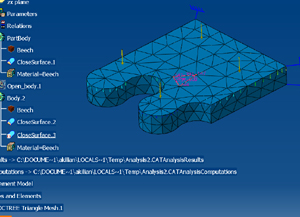

Proposed method - using finite element analysis to study the joint behavior.

Goal - to find an optimized joint configuration based on material properties

and geometry

Potential

resources

CATIA - Dassault System - generative structre modul

ADINA - Automatic,dynamic, incremental nonlinear analysis

openFEM.org - open source finite element tools library

Finite Element Procedures - Klaus Juergen Bathe

The modeling

of form rarely takes into account structural performance of the elements that

are being modeled. The proposal is to study how optimization and structural

analysis can be used to influence form making in design process.

Finite elment analysis seems like an approriate method to model material properties

and to give feedback to form making process.

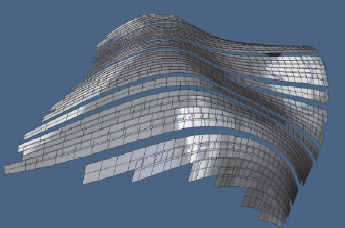

For instance a plank of wood laid onto a curved surface takes a certain path

based on its flexibility and crosssection and based on the curvature the surface

has. At a certain point the plank will not be able to follow the surface anymore.

One possible apporach could be to find distribution of planks on asurface

for optimal coverage based on the mateterial properties. (depending on level

I can achieve in FEM)